Ball valves Elephant BV3131P(3pc)-FP-F-ISO-H 16 bar, three-piece full bore flanged, stainless steel SS304, PTFE, with pneumatic actuator PA-DA, with pneumatic distributor 4M310-08 24V, with LSU APL- 410N EX, with manual Doubler MON1-250-T26-ISO, with ATU

Ball valves Elephant BV3131P(3pc)-FP-F-ISO-H 16 bar, three-piece full bore flanged, stainless steel SS304, PTFE, with pneumatic actuator PA-DA, with pneumatic distributor 4M310-08 24V, with LSU APL- 410N EX, with manual Doubler MON1-250-T26-ISO, with ATU - DN100 / 16 bar está agotado y se enviará tan pronto como vuelva a estar disponible.

No se ha podido cargar la disponibilidad de recogida

Entrega y envío

Entrega y envío

El costo de envío se determina durante el proceso de pago y varía según varios factores, incluido el tipo de producto, el tiempo de entrega, el proveedor de servicios y el país de destino.

Descripción

Descripción

Ball valve Elephant is used as a shut-off valve in heat and water supply systems, in steam, fuel and pneumatic systems with compressed air and neutral gases. Installation of valves of this series is possible in systems transporting liquid and gaseous media (water, oil, oils, steam, air, alcohols, glycol, etc.) not aggressive to valve materials.

Pneumatic rotary actuators are designed for automation of control process of industrial shut-off valves - gates, ball valves. Pneumatic actuators Elephant are designed for operation both indoors and outdoors. All internal and external parts are anticorrosive coated.

Pneumatic actuators 4M310-08 24V are used for control in pneumatic systems having NAMUR docking surface, for installation of actuators through through holes in the housing

Limit switch unit APL-410N EX is designed for visual and electrical signaling of end positions of the valve shut-off body. It is mounted from above on the surface of the pneumatic actuator and connected to the actuator shaft - DIN standard. The sealed box usually contains two sensors which monitor the position of the actuator shaft and signalize the end positions. Visual indication of the position can be observed on the housing of the unit there is a 3D visual indicator RED-CLOSED and YELLOW-OPEN.

Air treatment unit AFC2000 is designed to clean compressed air from moisture droplets and solid particles, remove condensate, automatically maintain the pressure at a preset level, supply lubricant from the tank in the compressed air flow to the elements of the pneumatic system with a wide range of throughput from 500 liters/minute to 10 000 liters/minute. The lubricator adds oil with a viscosity of 32 mm²/s (=cSt) at 40°C to the pneumatic system for further lubrication of control components such as pneumatic cylinders and pneumatic valves.

Technical characteristics of ball valves Elephant BV3131P(3pc)-FP-F-ISO-H 16 bar, three-piece full bore flanged, stainless steel SS304, PTFE, with pneumatic actuator PA-DA, with pneumatic distributor 4M310-08 24V, with limit switch unit APL- 410N EX, with manual Doubler MON1-250-T26-ISO, with ATU:

|

Nominal diameter DN, mm |

15–100 |

|

Operating pressure PN, bar |

DN15–50 – 40 |

|

Working medium temperature t, °C |

From -20 to +180 |

|

Working medium |

Water, steam, oil products, and other liquid or gaseous media neutral to the valve materials |

|

Connection to pipeline |

Flanged |

|

Type of passage section |

Full-bore |

|

Type of control |

Manual (handle) |

|

Additional option |

Electric or pneumatic actuator installation possible (ISO 5211-2001) |

Dimensions and sizes of ball valves Elephant BV3131P(3pc)-FP-F-ISO-H 16 bar, three-piece full bore flanged, stainless steel SS304, PTFE, with pneumatic actuator PA-DA, with pneumatic distributor 4M310-08 24V, with LSU APL- 410N EX, with manual Doubler MON1-250-T26-ISO, with ATU:

| DN | d, mm | D, mm | D1, mm | D2, mm | W, mm | f, mm | L±1.5, mm | T, mm | H, mm | Z-øM pcs-mm |

| 15 | 15 | 95 | 65 | 46 | 17 | 2 | 130 | 131 | 71 | 4-ø14 |

| 20 | 20 | 105 | 75 | 58 | 18 | 2 | 150 | 131 | 74 | 4-ø14 |

| 25 | 25 | 115 | 85 | 68 | 18 | 2 | 160 | 167 | 97 | 4-ø14 |

| 32 | 32 | 140 | 100 | 78 | 19 | 2 | 180 | 167 | 110 | 4-ø18 |

| 40 | 40 | 150 | 110 | 88 | 19 | 2 | 200 | 193 | 117 | 4-ø18 |

| 50 | 50 | 165 | 125 | 102 | 19 | 3 | 230 | 193 | 125,5 | 4-ø18 |

| 65 | 65 | 185 | 145 | 122 | 22 | 3 | 290 | 242 | 135,5 | 8-ø18 |

| 80 | 80 | 200 | 160 | 140 | 24 | 3 | 310 | 272 | 157 | 8-ø18 |

| 100 | 100 | 234 | 190 | 161 | 24 | 3 | 350 | 295 | 181 | 8-ø22 |

| 100* | 100 | 220 | 180 | 158 | 20 | 3 | 350 | 330 | 169 | 8-ø18 |

Materials of ball valves Elephant BV3131P(3pc)-FP-F-ISO-H 16 bar, three-piece full bore flanged, stainless steel SS304, PTFE, with pneumatic actuator PA-DA, with pneumatic distributor 4M310-08 24V, with limit switch unit APL- 410N EX, with manual Doubler MON1-250-T26-ISO, with ATU:

|

№ |

Name |

Material |

Quantity |

|

1 |

Body |

SS304/SS316 |

1 |

|

2 |

Shutter ball |

SS304/SS316 |

1 |

|

3 |

Bolt |

SS201/SS304 |

4–6 |

|

4 |

Nut |

SS201/SS304 |

6–12 |

|

5 |

Seal |

PTFE |

1 |

|

6 |

Stem |

SS304/SS316 |

1 |

|

7 |

Gland |

SS201/SS304 |

1 |

|

8 |

Cover |

WCB/CF8/CF8M |

2 |

|

9 |

Seat rings |

PTFE |

2 |

|

10 |

Thrust washer |

PTFE |

1 |

|

11 |

Locking nut |

SS201/SS304 |

1 |

Technical data of DA double-acting pneumatic actuators:

| Type of pneumatic actuator | DA - double-acting |

| Nominal pressure PN, bar | 12 |

| Working pressure, bar | 2...8 |

| Working medium | filtered compressed air |

| Maximum particle diameter of the working medium, µm2 | ≤30 |

| Ambient temperature, ⁰C | -20 to +80 |

| Swivel angle, ° | 0 - 90 |

| Swivel angle adjustment, % | ±5 |

| Position indicator | open/closed |

| Top connection standard | NAMUR |

| Air connection standard | NAMUR |

| Average life, cycles closed/open | 70 000 (for non-aggressive media and medium pressure and temperature values) |

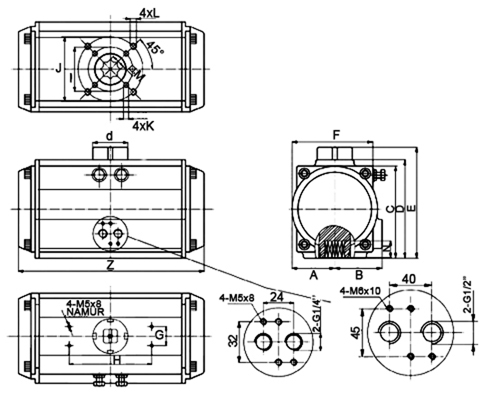

DA pneumatic actuators double-acting rotary actuators

Dimensions and mounting dimensions of DA double-acting pneumatic actuators:

| Model | A, mm | B, mm | C, mm | D, mm | E, mm | F, mm | G, mm | H, mm |

| DA-052 | 30 | 41,5 | 65,5 | 72 | 92 | 65 | 30 | 80 |

| DA-065 | 36 | 47 | 81 | 88 | 108 | 72 | 30 | 80 |

| DA-083 | 46 | 57 | 98,5 | 108,7 | 128,7 | 92 | 30 | 80 |

| DA-105 | 57,5 | 64 | 122,5 | 133 | 153 | 109,5 | 30 | 80 |

| DA-130 | 67,5 | 74,5 | 145,5 | 155 | 185 | 127,5 | 30 | 130 |

| DA-140 | 75 | 77 | 161 | 172 | 202 | 137,5 | 30 | 130 |

| DA-160 | 87 | 87 | 184 | 197 | 227 | 159 | 30 | 130 |

| DA-210 | 113 | 113 | 235,5 | 255 | 285 | 210 | 30 | 130 |

| DA-270 | 147 | 147 | 299 | 326 | 356 | 273 | 30 | 130 |

| DA-300 | 162 | 174 | 330 | 350 | 380 | 312 | 30 | 130 |

| DA-350 | 190 | 195 | 483 | 410 | 440 | 365 | 30 | 130 |

| Model | I, mm | J, mm | M, mm | N, mm | Z, mm | d, mm | K | L |

| DA-052 | 36 | 50 | 11x11 | 14 | 147 | 40 | M5x8 | M6x10 |

| DA-065 | 50 | 70 | 14x14 | 18 | 168 | 40 | M6x10 | M8x13 |

| DA-083 | 50 | 70 | 17x17 | 21 | 204 | 40 | M6x10 | M8x13 |

| DA-105 | 70 | 102 | 22x22 | 26 | 268 | 40 | M8x13 | M10x16 |

| DA-130 | 70 | 102 | 22x22 | 26 | 301 | 55 | M8x13 | M10x16 |

| DA-140 | 102 | 125 | 27x27 | 31 | 390 | 55 | M10x16 | M12x20 |

| DA-160 | 102 | 125 | 27x27 | 31 | 458 | 55 | M10x16 | M12x20 |

| DA-210 | - | 140 | 36x36 | 40 | 532 | 80 | - | M16x25 |

| DA-270 | - | 165 | 46x46 | 50 | 718 | 80 | - | M20x25 |

| DA-300 | - | 165 | 46x46 | 50 | 760 | 80 | - | M20x25 |

| DA-350 | 165 | 254 | 46x46 | 50 | 920 | 80 | M20x25 | 8xM16x25 |

Sketch of dimensions of DA double-acting pneumatic actuators

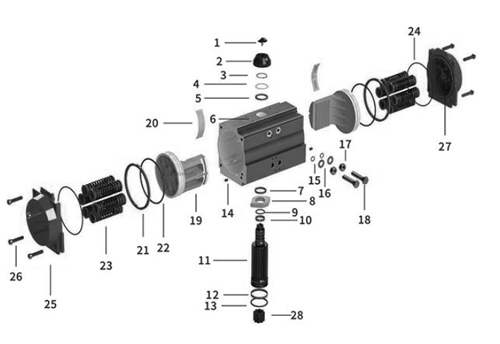

Materials of parts for DA double-acting pneumatic actuators:

| № | Part name | Material |

| 1 | Indicator screw | ABS plastic |

| 2 | Position indicator | ABS plastic |

| 3 | Spring clip | stainless steel 304 |

| 4 | Metal washer | stainless steel 304 |

| 5 | Pressure washer | engineering plastic |

| 6 | Housing | hard anodized extruded aluminum alloy |

| 7 | Pressure washer | engineering plastic |

| 8 | Limiter | alloy steel |

| 9 | Shaft sealing ring upper | NBR |

| 10 | Upper shaft sliding ring | engineering plastic |

| 11 | Shaft | nickel plated alloy steel |

| 12 | Shaft sliding ring lower | engineering plastic |

| 13 | Shaft O-ring lower | NBR |

| 14 | Plug | NBR |

| 15 | Seal ring of adjusting screws | NBR |

| 16 | Washer of adjusting screw | stainless steel 304 |

| 17 | Lock nut of adjusting screw | stainless steel 304 |

| 18 | Adjusting screw | stainless steel 304 |

| 19 | Piston | die-cast aluminum alloy |

| 20 | Piston guide plate | engineering plastic |

| 21 | Piston sliding ring | engineering plastic |

| 22 | Piston O-ring | NBR |

| 23 | Spring set | spring steel |

| 24 | Cover O-ring | NBR |

| 25 | End cap | cast aluminum with polyester coating |

| 26 | Cover screw | stainless steel 304 |

| 27 | Stop screw | stainless steel 304 |

| 28 | Adapter | carbon steel |

Material sketch of DA double-acting pneumatic actuators

Technical characteristics of the pneumatic distributor 4M310-08 NAMUR

| Design | Spool-type |

| Test pressure (body strength test. Not for operation!), bar | 10 |

| Working pressure (recommended range for normal operation), bar | 1.5 ÷ 8 |

| Valve type | 5/2 five-port, two-position |

| Working medium | purified air (40 µm filter fineness) |

| Operating temperature, °C | 0 to +60 |

| Actuation frequency | 5 cycles per second |

| Manual override | yes |

| Protection rating/insulation class | IP65/F |

| Connection to pneumatic actuator | NAMUR-compliant mounting surface (VDI/VDE3845) |

| Body material | anodized aluminum |

| Effective cross-sectional area, mm2 | 25 (Cv = 1.4) |

| Exhaust port dimensions (vent to atmosphere) | 2 - PT1/4” |

| Air inlet port size (to pneumatic valve) | G1/4” |

| Air outlet port size (to pneumatic actuator) | 2 x Ø19.2 mm |

| Response time, sec | 0.05 |

| Supply voltage, V | 220AC/24DC |

| Coil power | 220VAC – 5.5 VA/24VDC – 4.8 W |

| Weight, kg | 0.35 |

| Average service life, cycles | 10,000,000 |

Overall and installation dimensions of the pneumatic distributor 4M310-08 NAMUR

| A | C | D | E | F | G | H | I | K | L | J | N | M |

| mm | ||||||||||||

| 40 | 24 | 28 | 32 | 40 | 21,5 | 69 | 45 | 17,5 | 135 | 29,3 | 40 | 27 |

Sketch of the dimensions of the pneumatic distributor 4M310-08 NAMUR

Basic materials and parts of the pneumatic distributor 4M310-08 NAMUR

| № | Part Name | Material |

| 1 | Connector | Engineering plastic |

| 2 | Nut | POM + carbon steel |

| 3 | Coil | Copper |

| 4 | Control Elements | — |

| 5 | Plate | Carbon steel |

| 6 | Piston | POM |

| 7 | Control Valve Seat | Engineering plastic |

| 8 | Valve Body | Aluminum alloy |

| 9 | Spool | Aluminum alloy |

| 10 | O-Ring Seal | HNBR |

| 11 | Rear Cover | Engineering plastic |

| 12 | Filter | Synthetic material |

| 13 | Piston | POM |

| 14 | Spring | Stainless steel |

| 15 | Manual Override | Engineering plastic |

| 16 | Rear Seat | Aluminum alloy |

| 17 | Spring Seat | Aluminum alloy |

| 18 | Type C Towing Shackle | 65Mn |

Sketch of the dimensions of the pneumatic distributor 4M310-08 NAMUR

Technical characteristics of the air supply unit AFC2000:

| Operating pressure, bar | 8 |

| Maximum pressure, bar | 10 |

| Adjustable pressure range, bar | 0,5 ÷ 9 |

| Fracture pressure, bar | 15 |

| Air connection | 1/4" |

| Operating temperature, ⁰C | from -5 to +60 |

| Size of filtered particles, µm | 40 |

| Oil viscosity | ISO VG 32 |

| Weight, kg | 0,395 |

Technical characteristics of limit switch unit APL-410N EX:

| Body | all-weather IP65 explosion-proof Exd IIB T6 |

| Cable glands | 2 x NPT1/2” |

| Terminal strips | 8 points (0.05 - 2.5) mm2 |

| Position indicator | 0 - 90° (90° free rotation) CLOSED - red; OPEN - yellow |

| Switches/sensors | two mechanical switches two proximity sensors |

| Nominal voltage, V | 250 |

| Permissible ambient temperature, °C | from -25 to +80 |

| Service life, years | 10 |

Materials of limit switch unit APL-410N EX:

| Name | Materials |

| Enclosure cover and body | die-cast aluminum |

| Shaft | stainless steel |

| Indicator cover | polycarbonate |

| Cam | polycarbonate |

| Spring | stainless steel |

| Enclosure cover bolts | stainless steel |

| O-ring | NBR |

| Bushing | bronze |

| Sealing ring (shaft) | stainless steel |

| Ground terminal | stainless steel |

| Indicator | ABS plastic / polycarbonate |

| Bracket | stainless steel |

Especificaciones

Especificaciones

-

País de origen

-

Apertura de puerto

-

Temperatura máxima permitida

-

Tipo de conexión

-

Entorno operativoWater, Steam, Oil Products, Liquid Media, Neutral Media, Gaseous Media

-

Tipo de sello

-

Interruptores de límite

-

Tipo de actuador neumático

Reseñas (0)

Reseñas (0)

Pago y seguridad

Métodos de pago

Su información de pago se procesa de forma segura. No almacenamos los datos de su tarjeta de crédito ni tenemos acceso a la información de su tarjeta de crédito.

Preguntas frecuentes

Envío

¿A qué países realizan envíos?

¿A qué países realizan envíos?

Actualmente ofrecemos envíos dentro de Francia y en toda la UE, así como opciones de envío internacionales. Si tienes un destino específico en mente que no está en la lista, no dudes en contactarnos para obtener más información.

¿Cuánto tiempo tardaré en recibir mi pedido?

¿Cuánto tiempo tardaré en recibir mi pedido?

El envío estándar suele tardar entre 3 y 7 días. El envío al día siguiente está disponible para todos los pedidos nacionales (por un cargo adicional). Los tiempos de envío internacionales dependen de los productos y el destino (se calculan al finalizar la compra).

Devoluciones y reembolsos

¿Cómo devuelvo un producto?

¿Cómo devuelvo un producto?

Los artículos deben devolverse dentro de los 30 días posteriores a la recepción del pedido. Los artículos deben devolverse en las mismas condiciones en las que se recibieron, sin usar, con las etiquetas aún adheridas e incluir todo el embalaje original.

¿Cuánto tiempo tardaré en recibir mi reembolso?

¿Cuánto tiempo tardaré en recibir mi reembolso?

Los reembolsos se procesan dentro de los 7 días posteriores a que recibimos los artículos.